Olimac uses as many as 38 robots from ABB, a guarantee of the quality of their products

by Federico Antonelli

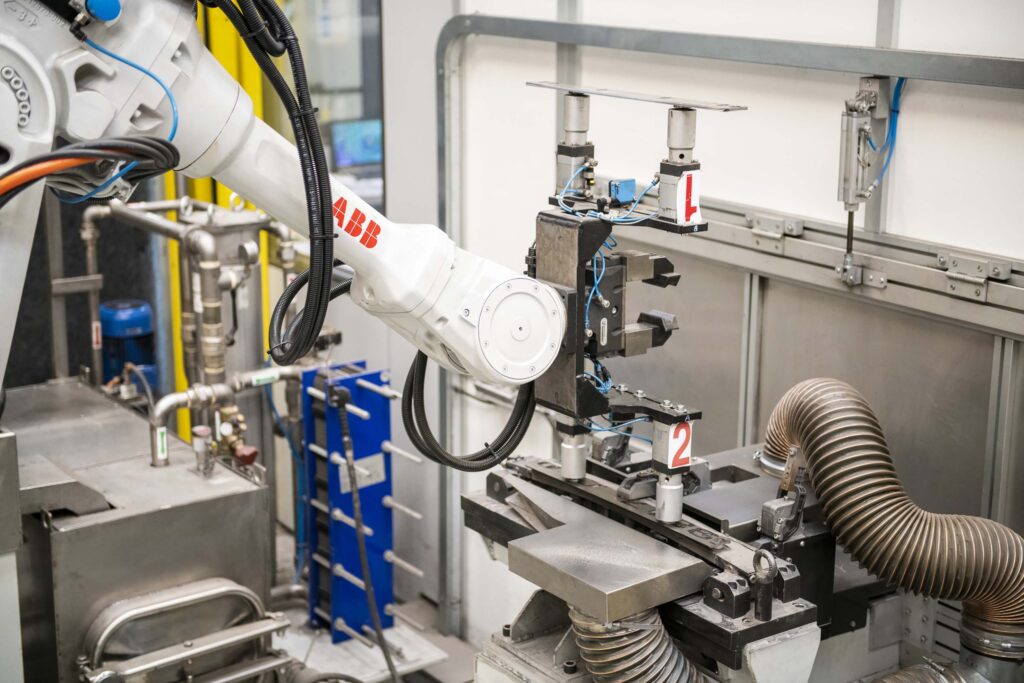

The first robot was installed in 1997 in the welding department and right from the start Olimac had no doubts about choosing ABB: “after years of collaboration, thanks to their reliability, we are increasingly satisfied with our choice”. Within the Olimac company, the need was to optimize production times, reduce error margins and have the cells work completely autonomously for a shift of at least eight consecutive hours without the need for human supervision. The robots have increased productivity by performing the most repetitive tasks, reduced error margins and lowered production costs. The 38 robots employed perform different functions such as welding, painting, 3D vision, assembly, quality control, and are also able to work simultaneously on the same workpiece.

Olimac, innovators since ever

It all started more than sixty years ago and since then they have never stopped. It was in the early 1950s, in fact, when Emilio Olivero designed and patented the Integral Head, a corn harvesting machine that was very innovative for the time, with a special amphitheater shape that allowed optimal feeding of the combine and increased production. Maria, Olivero’s daughter, married Giuseppe Carboni and together they founded Olimac in the Sixties, now in its third generation.

Over time, the family has continued to grow, seek out smart minds and professionals and pursue modern solutions in agricultural technology. “Over the years we have designed, built and patented machines that allow for higher performance each time,” says Lorenzo Carboni, who today, together with his sister Daniela, is the owner. “For example, our corn heads Drago are the only ones equipped with corn head plates, with automatic opening adjustment, which allow to harvest all the corn without any loss of cobs and kerneks, and therefore to ensure a total harvest and a higher profit for farmers”. Another important milestone in the company’s journey dates back to the early 2000s with the construction of the new facility in Margarita, in the province of Cuneo: a totally robotized industrial and technological facility, a unique in the world panorama of the sector. Thanks to this system, Olimac designs and manufactures all the components of the corn cobs entirely inside the plant.

A role for each robot

To meet Olimac’s needs, as many as 38 ABB robots have been over time included in the production process in different types of applications such as welding, assembling, mounting, manipulation, measurement, quality control, machine tending with picking from chests, painting, etc.. All applications were designed to the specific needs of Olimac directly by ABB Robotics Italy (now Global Solution Center for the General Industry) that has also realized them according to the “turnkey” formula. Among all, the main activity is welding, with a constant update of solutions to the latest developments in technology and has brought today, in addition to ABB’s traditional concepts of function package, the gantry solutions with multimove robots, the use of advanced sensors for the recognition and tracking of welding joints up to the latest cell realized where, unique case in its class, four coordinated robots operate simultaneously on the same workpiece.

This realization has been made possible not only by the latest technological developments and by a co-design approach that involves customer and supplier, but also thanks to the efforts made by Olimac to develop a more and more standard and modular product. Another innovative application is certainly the cladding with laser technology; it is an application of powder coating on the ends of the blades to increase the characteristics of strength and resistance, essential qualities in vehicles that by their nature must withstand accidental impacts and bad weather. This is a process in which the contribution of robots has proved essential because it allows people to avoid any contact with hostile environments and harmful substances. “The cells operate autonomously, guaranteeing repeatability and consistent quality, without constantly requiring the presence of an operator,” Lorenzo says. “In the past, all these operations were carried out manually, imposing alienating job, sometimes harmful to health and heavy to support.”

That’s how automation turns out to be an ally for people: in this way errors can be better controlled and avoided in terms of time, quality and safety.

Organization and control

It can be said that Olimac, with its current 38 robots, represents a sort of open-air catalog of what ABB (and in particular the Italian Glabal Solution Center) can offer for automation in the sector of agricultural machinery. But the collaboration with ABB is not limited to a supplier-customer relationship. “We have an open and proactive relationship” says Paolo Conca of ABB. “Olimac involves us in the design and our four-handed way of working allows us to keep all aspects of the project under control and deliver turnkey solutions, in this specific case without the need for system integrators. ” Olimac exports all over the world, especially to the USA, where Drago corn headers are the best-selling Italian deck plates. Despite this, they are not going to stop: “our challenge continues to be to constantly focus on research and innovation, so much so that our motto is innovate to grow”, Lorenzo concludes. And in this respect, robotics has proved to be a solution able to meet all production requirements: “the real strength of robots is their quality, their durability and their exclusive level of performance”. With the work of the robots, Olimac is able to have a completely autonomous production system and total control over everything that comes out of their company: “Thanks to robotics we have become completely independent, we are owners and managers of the entire production process”.